The valves of internal combustion engines are among the most highly stressed engine components. Inlet and exhaust valves are precision engine components used for sealing the combustion chamber and controlling the gas exchange process in internal combustion engines. Engine valves have to work reliably under severe mechanical and high thermal load conditions.

Inlet and exhaust valves have to be designed according to the engine application due to special load cases such as temperature, corrosion, wear resistance and mechanical loads from dynamics and combustion pressure. Valve design and material have to be selected according to these requirements.

The thermally lower stressed inlet valves are mainly cooled by the incoming gases. In contrast, exhaust valves are subject to high thermal loads and chemical corrosion during the exhaust cycle. Therefore, a wide range of materials and geometries are used in the design for exhaust valves.

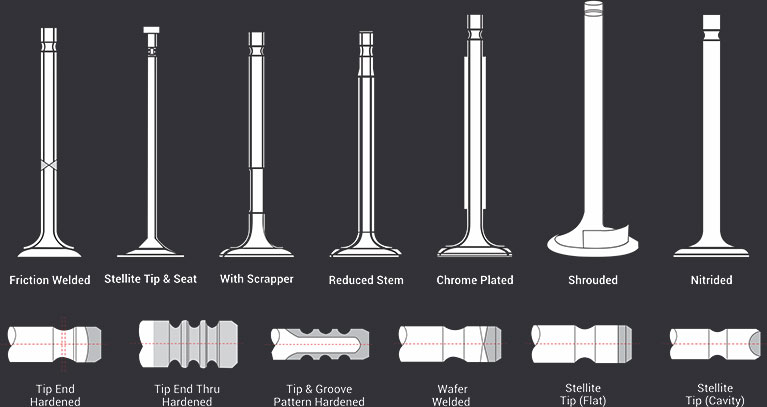

Special types of engine valves

BI METAL, NITRIDED, HARD CROME, SEAT & TIP STELLITE , DEFLECTOR